Racing Crankshafts and Rods 101

By the Ohio Crankshaft Staff.

The Ohio Crank crankshaft and rod terminology tech page explains some of the basics of motorsport crankshaft option.

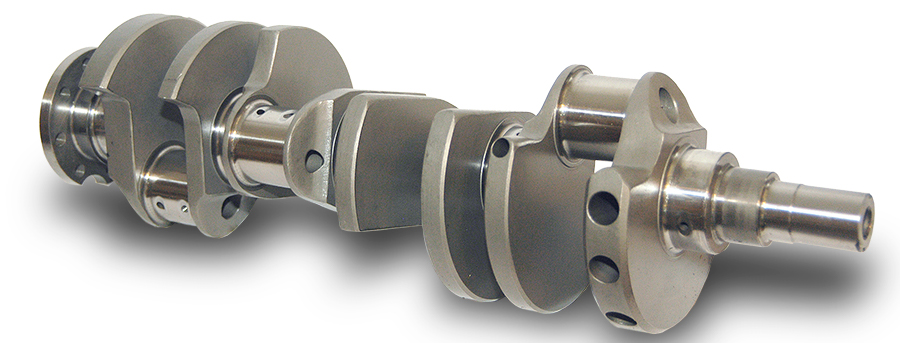

Cast cranks:

Aftermarket cast cranks are probably generally underrated. Most cast cranks, particularly nodular iron will be satisfactory in small block engines up to 400-450 HP and big blocks up to 500-600.

One factor is that engines above these points start to get pretty expensive, so that the difference between a cast crank at $200-$300 vs. a 4340 at $400-$600 doesn’t really have much effect on the total cost of the project.

Repairs:

Proper Straightening and grinding shafts should have no effect on the crankshaft. Straightening should also include some stress relieving.Steel and billet cranks: OEM steel cranks should be considered like aftermarket cast cranks.

Generally 4340 forged cranks should be adequate in most engines up to 1500 HP and billet shafts should considered above this point, although forged shafts are used everyday in some very high horsepower engines.

Rods:

All performance rods are forged, from various materials, and really don’t effect crankshaft life, although aluminum rods do seem to absorb some shock.Cracks: It is pretty unusual for a steel shaft to ever crack on a naturally aspirated engine, unless it has had a bearing failure. Blown motors tend to crack cranks because of their torsional loads, and lack of harmonic dampers.

Judging the potential for failures is an area where there is no substitute for experience.

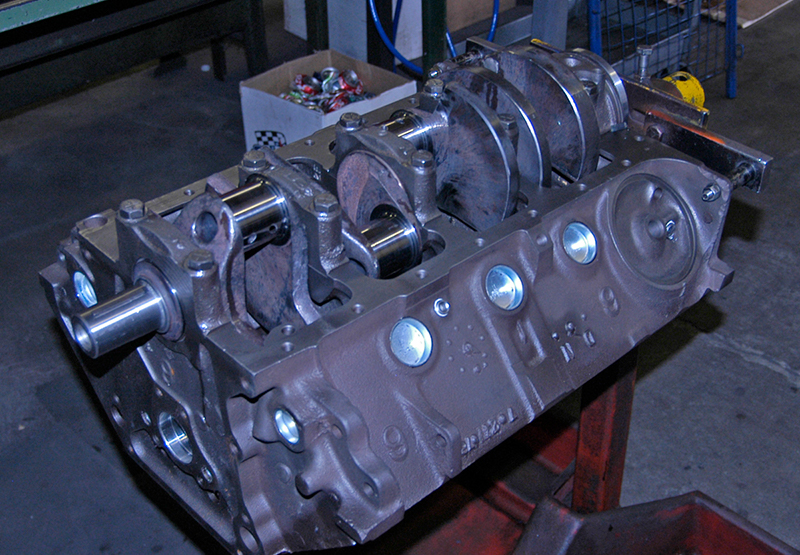

Maintenance:

Shafts should be cleaned and fluxed every season. Most times some polishing will be needed, but this not as easy as it may look. Care has to be taken not to taper the journal from the outer edge, to the center. This is usually caused by a belt type polisher used with too much pressure.

A polisher should never be used for stock removal, there are many over, and undersized bearings in as little as .0005 and they should be used to obtain the desired clearance.

Failures:

All bearing failures are caused by one thing. A lack of oil between the bearing and shaft. Of course, why that occurred isn’t always easy to determine. We continue to be amazed by the number of ongoing bearing problems that are solved simply by adding more oil to the crankcase.

This is particularly true on drysump systems. Lightening and knife edging: These do nothing to improve the reliability of the shaft, and very little to increase performance. Most racers would be better served to spend their money on other areas.

Repairing damaged shafts:

As a general rule, any shaft that isn’t cracked can be repaired. We rebuild our shafts by under-grinding to remove damaged material, then welding and grinding. We use a submerged arc system designed for crankshaft repair by the Gleason Company. Damaged thrust surfaces can also be repaired with this method.

View or download article PDF document.

All images and text copyright © -1994 to current date -Ohio Crankshaft and related companies involved .